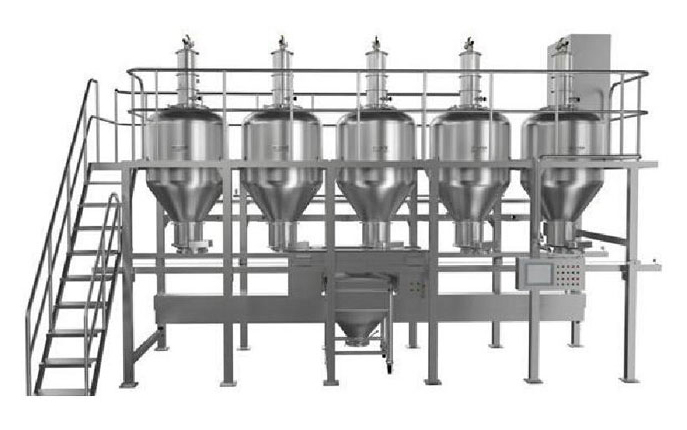

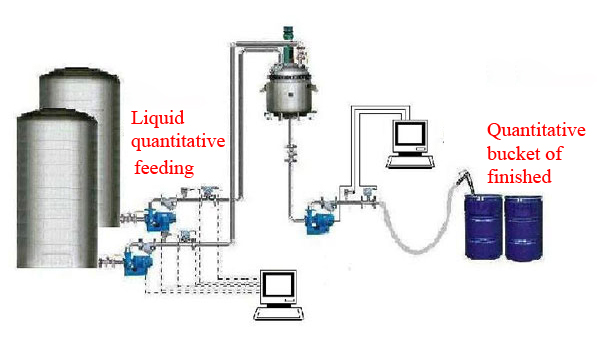

The automatic batching control system we introduced is a DCS suitable for cleaning plants and fine manufacturing plants. It is integrated with the other products of the factory, and has good openness. The control system is suitable for the cleaning agent and fine chemical industry formula, batch, discrete and continuous process characteristics. Its batch control program is particularly effective for the factory’s formulation and production. It is based on a stable system and can step by step to prompt and guide operators in the related process section to follow the established procedures. It also has a strict security classification function, so that the employees of different types of work have different rights, effectively avoid the occurrence of the whole batch of scrap because of the confusion of the division of labor, reduce the number of quality assurance personnel to be configured in the related process section, and reduce the production cost for them significantly.

Perfect automation solution for ingredients

Improve the performance, efficiency and reliability of the factory

Automatic batching control system

Typical application case

Beijing Rou Jia washing products Co., Ltd. is a daily washing product manufacturer. 2012 Yihai (China) has invested two production lines of cleaning agent for the production of Yihai brand in the enterprise. The two cleaning agent production line is using the automatic batching control system of the company. The two production lines were formally put into use in 2013. After the production line was formally put into use, they quickly replaced their previous artificial feeding methods. The application of automatic batching control system in their production not only improved the quality and production of the ingredients, but also greatly reduced the production.

Design description

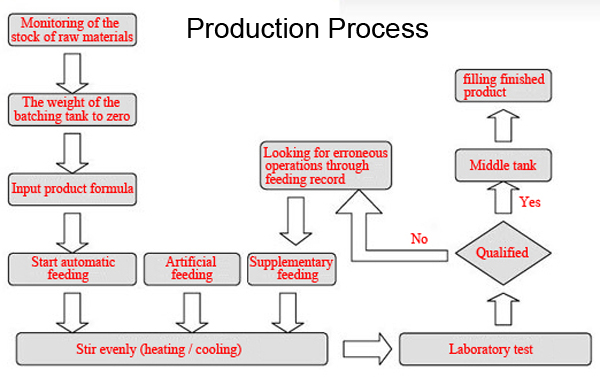

When the quality of the product is problem, we can find out the wrong operation of the time or analyze the quality of the raw material by adding material record, so as to analyze the cause of the production quality accident and improve the reliability of the product quality.

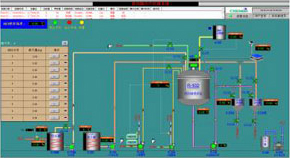

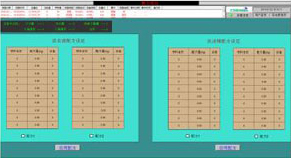

Humanized Interface

There are obvious steps on the main interface. The workers only need to operate according to the given steps. It reduces the wrong operation of the workers, also facilitates the operation of the new employees, and the alarm function. When the tank level is too small, the alarm will be produced, and the workers are reminded to take measures, or the weight of the mixing kettle is more than the weight of its upper limit. The system will immediately take measures to stop the pump and stop the valve

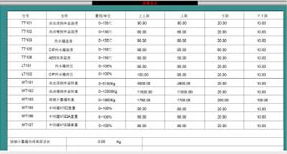

Recipe management

Specific to the formulation, the process of adding materials to various methods provides a formula management, which reduces the operation difficulty of the workers and reduces the product quality accidents caused by the mistake of the formulation.

Parameter protection

When the worker needs to modify the process parameters, the process manager can only enter the administrator’s password after entering the administrator’s password to modify the parameters to ensure that the production parameters can be effectively controlled.

HDC company has a complete set of solutions for the whole production cycle, which meets the requirements of end users and industry specifications to help them achieve quality control and meet the requirements of consumers. This series of strategic measures has made HDC company a professional preferred partner in the chemical industry, providing a comprehensive and rich solution for the entire product life cycle.