HDC is dedicated to the automation control and complex process optimization of the chemical industry, including solutions based on OCS or PLC. HDC also provides a series of customized software for chemical plants. It plays a very long and effective role in many factory management. Hardware and software partners: CHINT, SIEMENS, Ross Ment, China Ding.GE and other world-class suppliers. Hongye will work together with you to build a long-term mechanism for the safe production of dangerous chemicals.

Automation solution for hazardous chemicals production

Construction of long-term mechanism for safety production of dangerous chemicals

Based on the experience of HDC operation in the field of hazardous chemicals automatic control, it is suggested that measures should be taken from the following four aspects:

(1) process improvement

According to the toxicity / explosion of raw materials and products, we should consider improving the production technology from the angle of safety coordination.

(2) improve the performance of the equipment state

Improve and enhance mechanical strength, pressure, wear and corrosion of production equipment, and reduce safety accidents caused by equipment failure.

(3) equipment self-control device

It is suggested that the chemical equipment involved in the anti dangerous process must be equipped with the automatic control system, the toxic and harmful, flammable and explosive gas leakage detection and alarm system and the fire alarm system, and so on. The safety and reliability of the hazardous chemical production equipment can be improved by uninterrupted monitoring by 24 hours of the dangerous source of the automatic control equipment.

How to improve the security of the automatic control system

Process improvement. The improvement of equipment performance needs a long period of time, and the equipment of the automatic control system and the strengthening of management and training can improve the accident prevention and control ability of the hazardous chemical enterprises and the essential safety level of the enterprise in a relatively short time.

The automatic control system generally realizes the dual functions of production control and safety supervision / emergency shutdown, and the safety supervision functions such as alarm and parking are generally realized for the modified face chemical production equipment and automatic control system. The automatic control system has the functions of monitoring, alarm, and discovering hidden dangers.

The following features ensure the safety of hazardous chemicals production units:

Typical application cases

DCS safety monitoring and control system

It is a typical fine chemical plant. It has some flammable and explosive gases in production and storage, such as chlorine and ammonia, all of which belong to dangerous chemicals. In produ ction, materials are easily caused by misoperation or equipment damage.

In April 2013, the DCS safety control system of HDC. was adopted. The safety monitoring function of the fine synthetic workshop and dangerous goods warehouse was realized. The hidden danger in production was cleared.

The whole automatic control system has realized the initial installation idea well and runs smoothly. The stability and convenience of the system have been tested repeatedly and performed well. The data collection and control of all points in the fine synthesis workshop, the display of the reaction temperature of the reactor, the record of the historical trend and the warning letter and transmission are realized. A series of functions, such as the accurate display of the temperature rise curve of the reactor and emergency shutdown chain control, have been successfully realized, ensuring the safety of production. In addition, we have realized the contrast function of the temperature curve of the reactor. It is convenient for the factory to compare the production situation before and after the comparison, to find the production accident and to find the optimal production temperature and operation method.

safety monitoring system PLC

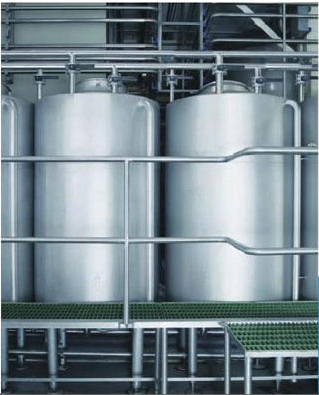

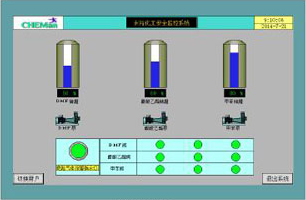

It needs to use DMF, ethyl acetate and toluene in the process of production. These materials are also inflammable, explosive and toxic chemical raw materials. There are a large number of these materials in its tank area. These materials must have 24 hour monitoring equipment for these materials.

In 2014, the pLc safety monitoring system of HDC was adopted. It not only realized the function of safety monitoring and safety production in the workshop, but also remotely monitor the condition of the material in the tank area.

The characteristic of this system is that the cost is cheap. Short installation period and less maintenance. The main functions of the system are two aspects. One is to monitor the real time level in the tank of the tank and provide the workers with the data of the stock of the production material. It is convenient for the workers to operate. At the same time, when the tank level is too high, the warning sounds will be produced and the related protection actions of the stop pump stop valve are taken immediately. Two, when the flammable or poisonous gas leaks in the workshop or tank farm, it also triggers the protective work such as stopping the pump and stopping the valve.

In addition, we also provide a historical trend view function to facilitate managers to master production consumption in the workshop so that managers can better develop raw materials procurement plans.