Glycerin Distillation and Bleaching from Air Liquide Engineering & Construction is a technology for purifying crude glycerin to create pharmaceutical glycerin with a co-product of technical grade glycerin. More than 99.7% purity can be obtained using this method.

Maximizing the yield

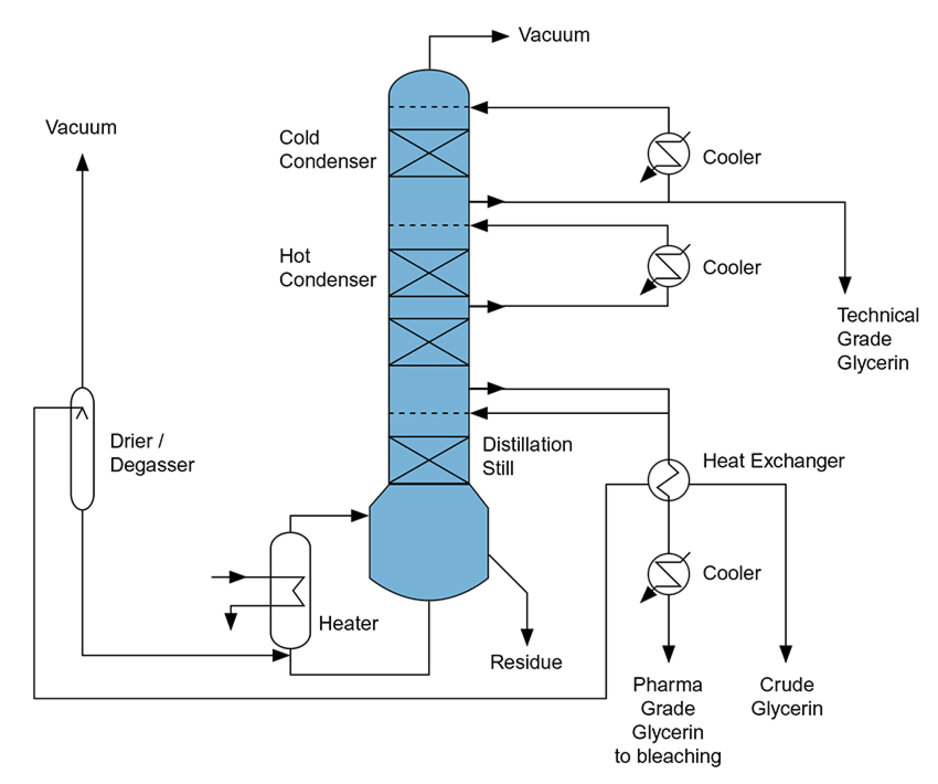

The feedstock for this process is crude glycerin from biodiesel or oil splitting plants. In the first step, the unit is heated to 175°C and a vacuum distillation is used to separate the glycerin from organic components and salts. The glycerin yield is maximized by sending residue from the bottom of the column to a post-distillation still. Through decantation, salt can be separated from the residue, reducing waste and further increasing glycerin recovery.

To create pharmaceutical grade glycerin with a purity of over 99.7%, the product is then polished through bleaching. This involves adsorption at fixed beds of activated carbon, a process that creates a by-product of technical grade glycerin with a purity of 85-90%.

Advantages

- Produces 99.7% pure, pharmaceutical grade glycerin

- By-product is technical grade glycerin (85-90% purity)

Key figures

- Capacity: 10 tons per day to 600 tons per day

- Operating Expenditures: 35 United States Dollar (USD)/ton