Glycerine is a versatile chemical product used in large range of fields. The use of refined Glycerine in the pharmaceutical industry as a solvent and as substrate for medications; in cosmetics industry for the production of soap and for the preparation of numerous cosmetic products; in the food industry for the production of syrups, soft drinks, bakery products, preservation of fruit and vegetables; in agriculture as an additive are just the most important applications. The refined Glycerine is non-toxic, non-allergenic, antiseptic, acts as stabilizer, preservative and emollient; is hygroscopic; thanks to this features it is so largely employed.

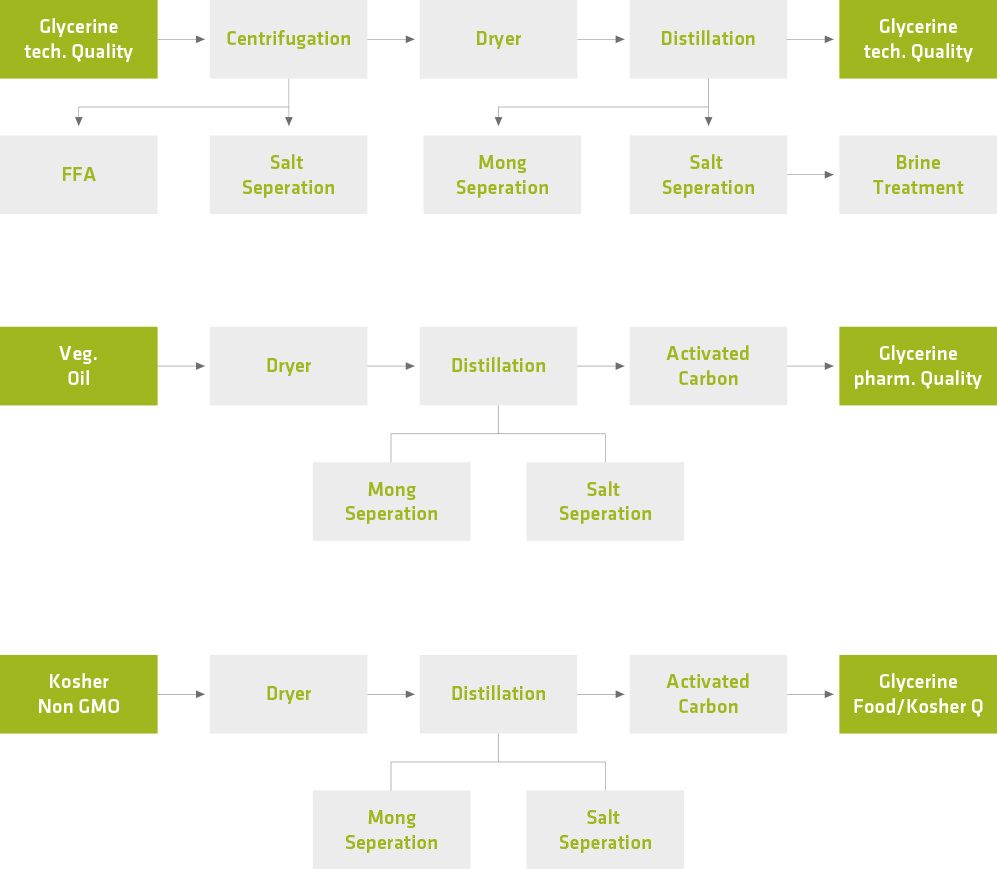

Depending on the applications, different quality is required. To meet the quality standard from the technical grade until the pharmaceutical and kosher, the purification process is a determinant factor to ensure the required quality.

KVT has developed and successfully established a process to refine Glycerine, using raw Glycerine from the biodiesel production.

The glycerine purification is based on the following steps:

- Neutralisation and drying

- Methanol rectification

- Distillation, rectification

- Mong desalination

The resulting pharmaceutical/Kosher Glycerine is of excellent quality and has a biogenic content of 99.7 %. The process can be adjusted for different raw Glycerine qualities coming from different industrial fields. So you can produce different Glycerine grades for different applications.

Your added value at a glance:

- Production of pure pharmaceutical Glycerine from sustainable raw materials with a biogenic content of 99.7 %

- Minimum final by-products with the Mong desalination unit

- Continuous and independent supply of raw materials, as raw Glycerine is available worldwide year round.

Industry applications summary:

- Chemical industry

- Pharmaceutical industry

- Food industry

- Cosmetics industry

- Detergents industry

- Plastics and lacquer industry

Process Overview